- Home

- Products

- Vacuum Packaging Machine

- Double Chamber Vacuum Packaging Machine

- DZ-600-2SB Double Chamber Vacuum Packaging Machine

DZ-600-2SB Double Chamber Vacuum Packaging Machine

DZ-600-2SB Double Chamber Vacuum Packaging Machine

DZ-800-2SB Double Chamber Vacuum Packaging Machine

DZ-700-2SB Double Chamber Vacuum Packaging Machine

DZ-600-2SB Double Chamber Vacuum Packaging Machine

DZ-500-2SB Double Chamber Vacuum Packaging Machine

Description

DZ-600-2SB double chamber vacuum packing composes flat vacuum chamber. It is easy to clean during the operation. This method of vacuum packaging is utilized when the highest level of vacuum is required.

Application of Chamber Vacuum Sealer

DZ-600-2SB double chamber vacuum packing is applicable to vacuum packing of food, medicine, marine food, chemical product and electrical product.

Technical Characters of Chamber Vacuum Sealer

1. Microcomputer control system is used for setting precise and stable vacuuming, sealing time according to different packing materials and packing requirements, which is easy to operate.

2. Equipped with big capacity vacuum pump, double chamber vacuum packing could achieve maximum vacuum degree in short time and improve working efficiency.

3. The "V” shaped chamber lid gasket is made of high-density material, which ensures sealing performance.

4. Service life of sealing tape can be extended by using compressed and wearing resistance material, and change frequency can be also reduced.

5. The double chamber vacuum packing is equipped with an emergency stop switch which can be pressed in case of abnormal condition to terminate all ongoing work programs and guarantee the safety of equipment and personnel.

6. The heavy-duty casters (with brake) on the machine features superior load bearing performance, so that the user can move the machine with ease.

7. This machine models is vary from small tabletop units to large floor standing single and double vacuum chambers.

8. The double chamber vacuum packing is primarily made of 304 Stainless Steel. Chamber vacuum sealer offers a high level of vacuum.

Technology Specification

|

Model |

DZ-600-2SB Double Chamber Vacuum Packing |

|

Machine Dimensions(mm) |

1450 × 720 × 1025 |

|

Chamber Dimensions(mm) |

720 × 560 × 120 |

|

Sealer Dimensions(mm) |

600 × 8 × 2 |

|

Vacuum Pump(m3/h) |

20 × 2 |

|

Power Consumption(kW) |

0.9 × 2 |

|

Electrical Requirement(v/Hz) |

220/50 |

|

Production Cycle(times/min) |

1-2 |

|

Net Weight(kg) |

215 |

|

Shipping Dimensions(mm) |

1530 × 800 × 1190 |

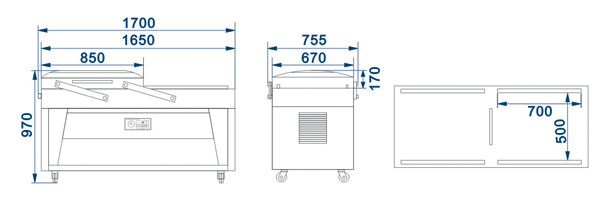

Sketch Map

Flexible and reliable packaging equipment systems

Multiple package sizes, Quick mold switching

Intelligent control / Precision parts

Complete Hermetic Seals Every Time

-

Vacuum Sealers and Vacuum Packaging Machines

- Continuous Rolling Type Vacuum Packaging Machine

- Automatic Heat Sealer

- Automatic Tray Sealer

- Tabletop Vacuum Sealer

- Vacuum Tray Sealer

- Semi-automatic Vacuum Sealing Machine

- Floor Top Vacuum Packaging Machine

- Double Chamber Vacuum Packing Machine

- Vertical External Vacuum Sealer

- L-Seal Hood Shrink Packaging Machine

-

- Address: Floor 7, Greenland Building, No.5558 Chuansha Road, Pudong District, Shanghai, China

- Post code: 200120

- E-Mail: landytop@hotmail.com