- Home

- Products

- Vacuum Packaging Machine

- Table Top Vacuum Packaging Machine

- DZ-435/ PJ Table Top Vacuum Packaging Machine

DZ-435/ PJ Table Top Vacuum Packaging Machine

DZ-435/ PJ Table Top Vacuum Packaging Machine

DZ-350/MD Table Top Vacuum Packaging Machine

DZ-350/M Table Top Vacuum Packaging Machine

DZ-300/PJ Table Top Vacuum Packaging Machine

DZ-260/PD Table Top Vacuum Packaging Machine

Machine Description

DZ-435/ PJ table top vacuum sealing machinery works by removing the air in a bag prior to sealing. This chamber vacuum sealer is primarily used for shelf life extension, volume reduction, and corrosion protection. DAJIANG MACHINERY is one of the most extensive lines of industrial vacuum packaging machines in the industry.

We also manufacture a full line of industrial chamber vacuum sealer, ranging in size from tabletop models to larger high production vacuum packing machines.

Application of Vacuum Sealing Machinery

This DZ-435/ PJ chamber vacuum sealer is widely applied in vacuum packaging of various food, medicine product, electrical product and chemical product.

Technical Characters of Vacuum Sealing Machinery

1. The lid is made of high-quality acrylic material, which is solid and transparent for observing the packing situation within the vacuum chamber at any time.

2. The chamber vacuum sealer is made primarily of 304 Stainless Steel to ensure its elegant appearance as well as the anticorrosion in harsh caustic environment.

3. The "V” shaped chamber lid gasket is made of high-density material, which ensures sealing performance.

4. Service life of sealing tape can be extended by using compressed and wearing resistance material, and change frequency can be also reduced.

5. The vacuum chamber is bright, clean, spacious and easy to clean.

6. The special labor-saving hinges on the lid markedly reduce the labor intensity of operator in daily work, so they can handle it with ease.

Technology Specification

|

Model |

DZ-435/PJ Chamber Vacuum Sealer |

|

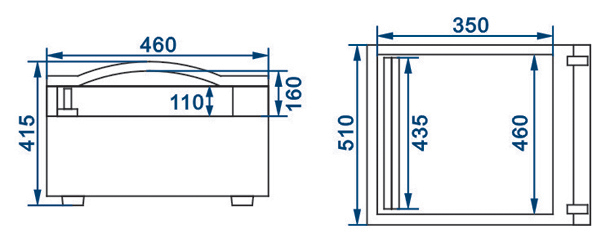

Machine Dimensions(mm) |

510 × 460 × 415 |

|

Chamber Dimensions(mm) |

350 × 460 × 160 (110) |

|

Sealer Dimensions(mm) |

435 × 8 |

|

Vacuum Pump(m3/h) |

10 |

|

Power Consumption(kW) |

0.37 |

|

Electrical Requirement(v/Hz) |

220/50 |

|

Production Cycle(times/min) |

1-2 |

|

Net Weight(kg) |

44 |

|

Shipping Dimensions(mm) |

610 × 490 × 420 |

Sketch Map

Flexible and reliable packaging equipment systems

Multiple package sizes, Quick mold switching

Intelligent control / Precision parts

Complete Hermetic Seals Every Time

-

Vacuum Sealers and Vacuum Packaging Machines

- Conveyor Belt Vacuum Machine

- Single Chamber Vacuum Packaging Machine

- Special Tray Sealer

- Double Chamber Vacuum Packing Equipment

- Automatic Heavy-duty Bags Packaging Machine

- Retort Sealing Machine

- Single Chamber Packing Machine

- Semi Automatic Tray Sealer

- Vertical External Vacuum Sealer

- Automatic Vacuum Packing Machine

-

- Address: Floor 7, Greenland Building, No.5558 Chuansha Road, Pudong District, Shanghai, China

- Post code: 200120

- E-Mail: landytop@hotmail.com